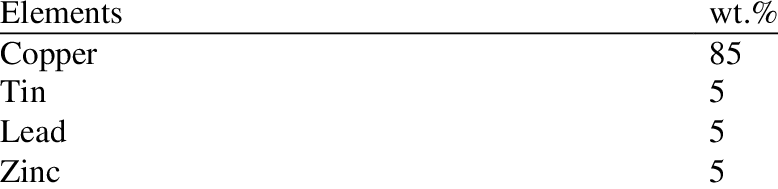

Chemical composition of the lead-free brass

5 (521) In stock

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

Chip Thickness Ratio by Feed Rate

Contours of average Von Mises stress.

Bending moment of the deck resulting from Case (1) and Case (2) under

Chemical composition of the lead-free brass

Chemical composition of brass electrode

Chemical composition of brass alloy

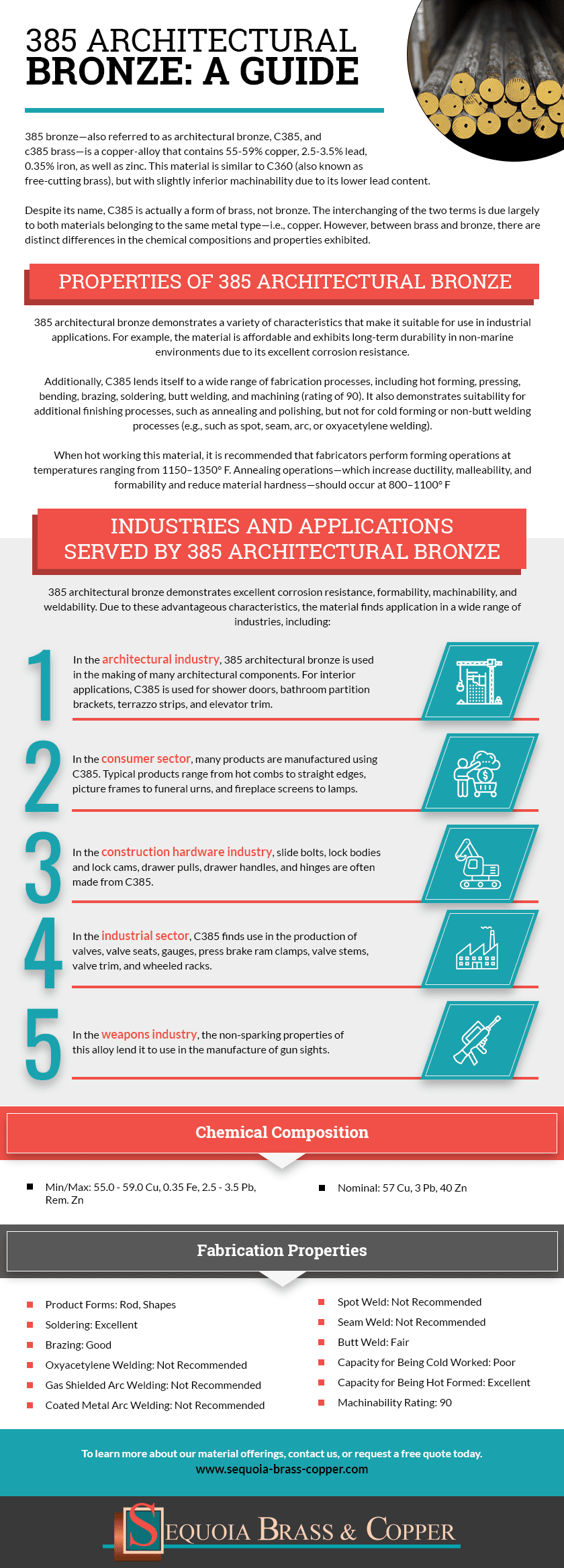

Alloy 385 Architectural Bronze - Sequoia Brass and Copper

Chip Thickness Ratio by Feed Rate

Lead Free Brass Rods

Material Physical Properties

Machinability of Lead-Free Brass – A comparative study

Eco Brass is the Solution to Avoid the Dezincification of Brass

Brass material datasheet - LORRIC

Composition of duplex brass alloy

Round Square Hexgonal Brass Bar and Brass Rod Cuzn35 C2680 H62 Grade - China Brass Bar, Brass Rod

Under Bra Rash

Under Bra Rash- Moose Creek and Easy Street Loop, British Columbia, Canada - 45 Reviews, Map

Gymshark Vital Seamless Leggings Womens Size XS Ash Teal Marl Compression

Gymshark Vital Seamless Leggings Womens Size XS Ash Teal Marl Compression Dumbbell Side Split Squat Exercise Guide

Dumbbell Side Split Squat Exercise Guide Avia Women's Medium Impact Strappy Sports Bra

Avia Women's Medium Impact Strappy Sports Bra Black 'Heat Active' Thermal Crew Neck Top from Tu at Sainsbury's

Black 'Heat Active' Thermal Crew Neck Top from Tu at Sainsbury's