Threaded Holes: An Introduction and Guidelines

4.8 (791) In stock

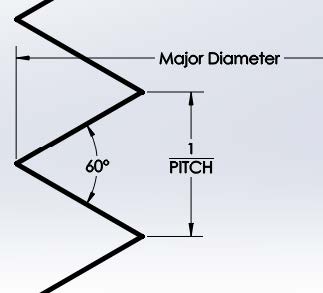

Threaded holes are integral aspects of mechanically fastened parts. They are easy to add with CNC machines. Threads are usually added last after most other aspects of the part have been machined. Getting it wrong and being forced to scrap a part can be a very costly mistake. There are several factors designers and machinists must consider when they approach threaded components. Careful planning along with the following guidelines will make the addition of threaded holes go smoothly.

Guide to Repairing Old Screw Holes in Fiberglass

125mm Lathe Flange, 6 Holes Flange Coupling Connector Chuck Flange

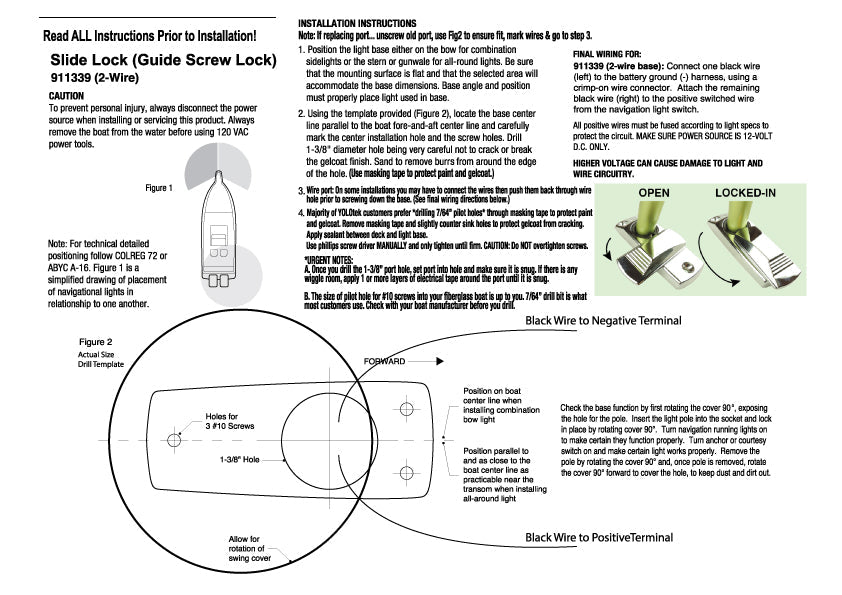

Attwood Guide-Screw Locking NavLight Port Kit [Rectangle] – YOLOtek

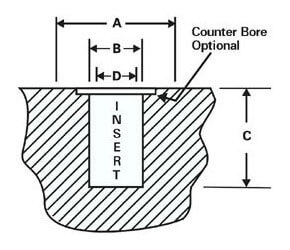

Threaded Metal Insert Design Guidelines

Metric V-TapGuide® The tap guide holes are sized for ANSI Standard Ground Thread Metric Taps. The Metric V-TapGuide® (9 holes) handles tap sizes: 1.6,

Tap Guide Tool - Metric Sizing V-TapGuide - Helps start threaded holes straight & help prevent tap breakage - Lifetime Warranty - Tap Jig

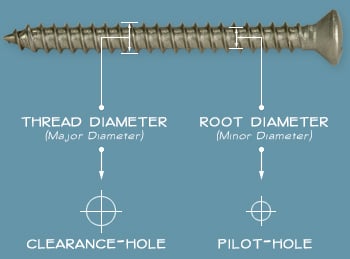

Make Threaded Holes: Considerations For Tapped A Hole - WayKen

Test fixture (1-lower rail; 2-guide rod; 3-pulley; 4-slider; 5

How to drill a guide hole without ruining your guitar

Adjustable spring-tensioned tap guide is used with a tap to thread holes in machining operations Tap guide aligns tap with the center of the hole and

Spring Center Knurl Tap Guide Tool to Align Tap for Threading Lathe Mill Jig Bore

Feasibility of Threaded Holes for Rapid Prototyping

Make Threaded Holes: Considerations For Tapped A Hole - WayKen

CNC Machining Threaded Holes Guidelines for Milling & Turning

9 Of The Most Striking Skyscrapers With Holes In Them

Fake Holes Hand Latex Wounds Stock Photo 2284426255

Differences Between Pizza Pan with Holes vs. No Holes– Pizza Bien

YU & ME Body Shaping Jeggings Black – Shush

YU & ME Body Shaping Jeggings Black – Shush Adidas Womens Sports Bra Extra Small Blue White Compression

Adidas Womens Sports Bra Extra Small Blue White Compression Uniqlo, Pants, Ultra Stretch Active Jogger Pants Uniqlo

Uniqlo, Pants, Ultra Stretch Active Jogger Pants Uniqlo Black High Waist Cut Yoga Leggings High Stretchy Butt - Temu

Black High Waist Cut Yoga Leggings High Stretchy Butt - Temu- Spanx Plus OnCore Open-Bust Mid-Thigh Bodysuit

- Michael B. Jordan Knocks Us Out In Steamy Underwear Campaign for