Lubricants, Free Full-Text

4.7 (526) In stock

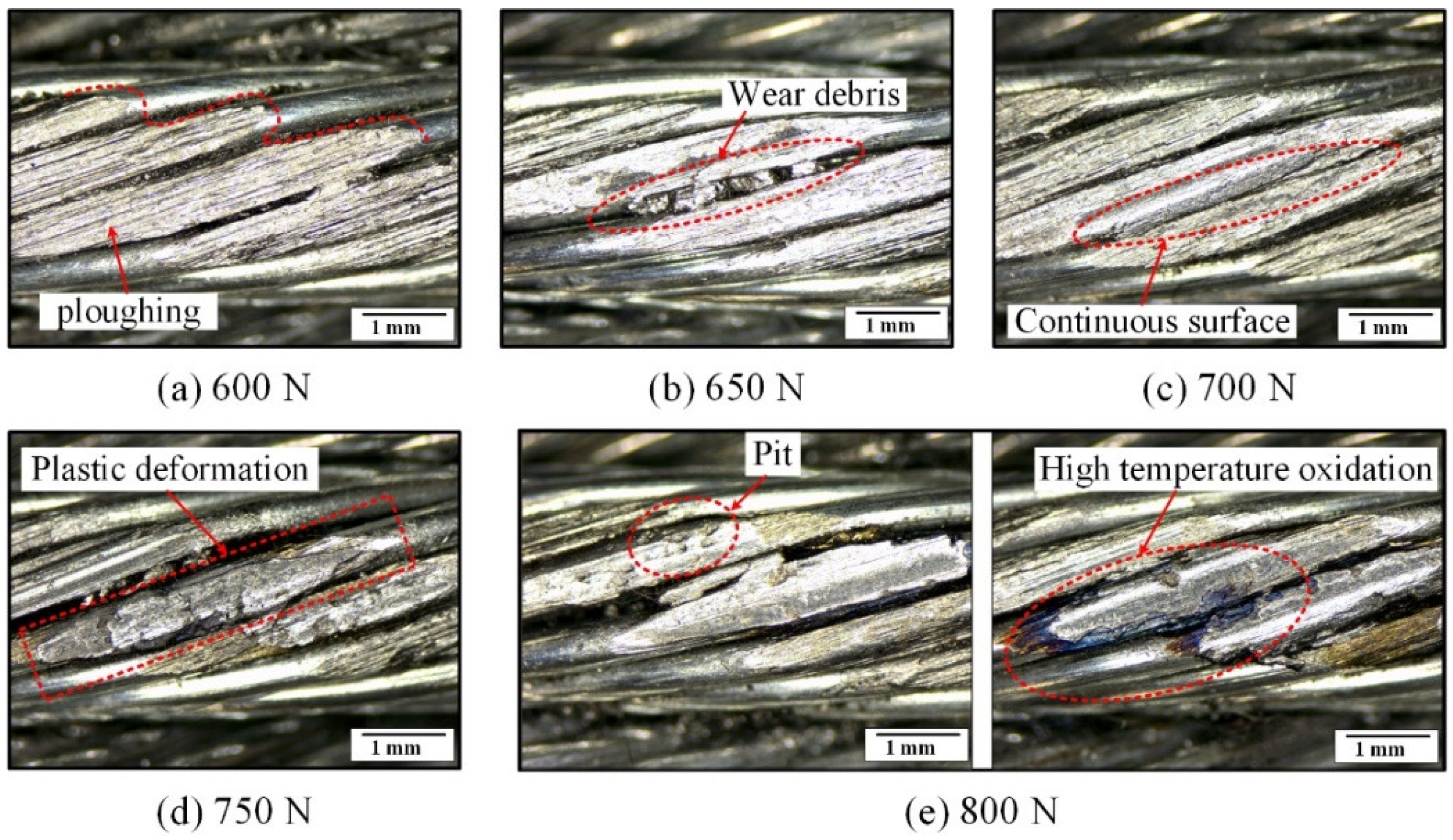

Surface wear caused by contact between crane wire rope and a pulley seriously affects the mechanical properties of the wire rope. In this study, the tribological behavior of wire rope was investigated using a homemade rope–pulley sliding friction test rig. Then, the influence of different surface wear on the bending fatigue life of the rope samples was analyzed. The results show that the friction coefficient (COF) decreases with the increasing sliding distance. It reaches a minimum of approximately 0.52 when the contact load is 700 N. The surface temperature of the wire rope rises rapidly and then gradually stabilizes. The maximum temperature rise fluctuates in the range of 50 °C to 60 °C with increasing contact load. The wear scar of the wire rope is irregular, and the maximum wear width increases from approximately 1.94 mm to 2.45 mm with the contact load. Additionally, increased contact load leads to smoother wear surface of wire rope, and the wear mechanisms are mainly abrasive wear and adhesive wear. Additionally, surface wear leads to a decrease in the bending fatigue life of wire ropes, and degradation of anti-bending fatigue is more serious under a larger sliding contact load.

Download PDF of All Type of Lubricant Information

Experimental assessment of thermal and rheological properties of

Lubricants, Free Full-Text

coatings Archives - About Tribology

MORRIS Ring Free XHD 20W Monograde Engine Oil - Ashley Power Ltd

VPS International bv Type Full Synthetic Engine Oil SAE 5W30 API

TAN TBN, 59% OFF

Lubricants, Free Full-Text

Lubricants, Free Full-Text

White Rayon Covered Wire #21 - Judith M Millinery Supply House

Crane Wire Rope Damage And Wear

Wire Rope Slings for Rigging & Material Handling [2019] – MTN Shop EU

Construction professional workers wear safety harnesses and safety

Wire Frame Glasses: How To Wear Them Like Kendall Jenner, Justin

Postural Orthostatic Tachycardia Syndrome – Overview and Focus on

Postural Orthostatic Tachycardia Syndrome – Overview and Focus on- Spanx Higher Power Ladies Shorts

Cosmolle Activewear Fashion That Is Anything But Boring

Cosmolle Activewear Fashion That Is Anything But Boring BRUSHED RIBBED PANTS - Oyster-white

BRUSHED RIBBED PANTS - Oyster-white- Richard E. Veitch Named PRO-TEC Coating Company's New President

- Photos of Flex Fitness Crossfit And Spa, Sector 57, Sector 56, Gurgaon