Materials, Free Full-Text

4.5 (588) In stock

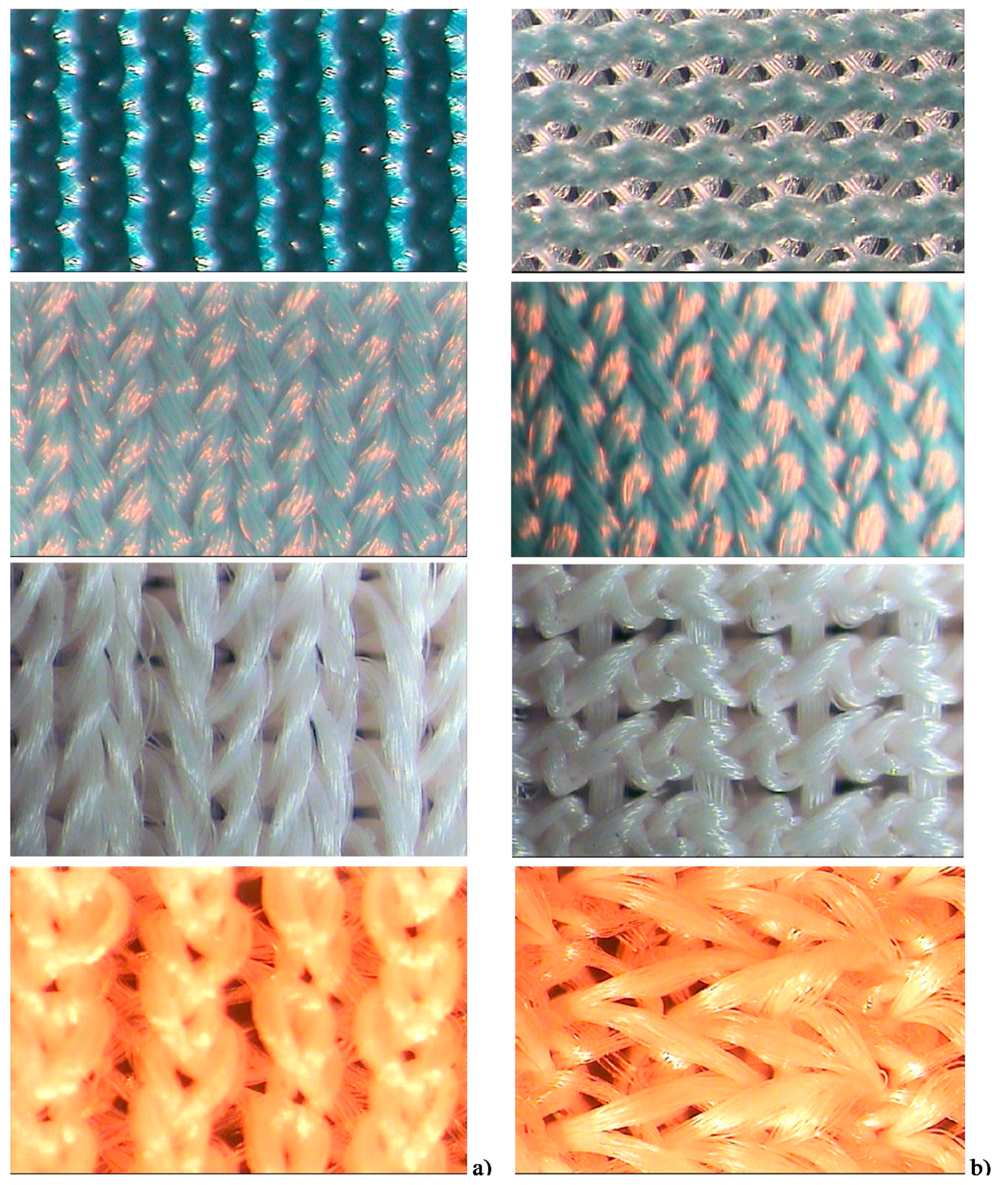

The aim of this study is to develop a mathematical model for the prediction of compression pressure based on fabric parameters, such as engineering stress, engineering strain and engineering modulus of elasticity. Four knitted compression fabrics with different fibrous compositions and knit structures were used. Rectangular-cut strips were employed for the force–elongation characterization of the fabrics. The experimental pressure values between the fabric and rigid cylinder were assessed using a Picopress pressure measuring device. The mechanical and physical parameters of the fabric that influence the interface pressure, such as strain, elasticity modulus/stress and thickness, were determined and integrated into Laplace’s law. A good correlation was observed between the experimental and calculated pressure values for all combinations of fabrics, mounted with variable tension on the cylinder. Over the considered range of pressures, the difference between the two datasets was generally less than 0.5 mmHg. The effect of washing after five, ten and fifteen washing cycles on the fabric–cylinder interface pressure was found to be significant.

Metals, Free Full-Text, simulation unclogger

Free Download Construction Materials, Methods and Techniques Full

Materials An Open Access Journal from MDPI

Materials, Free Full-Text, Heat Transfer

Free Download Fundamentals of Building Construction: Materials and

Materials An Open Access Journal from MDPI

PDF) Materials Engineering

1 X 2 5 8 Label Template Unique Micromachines Free Full Text 2d

Materials An Open Access Journal from MDPI

Compression molded Kevlar fabric with EVA foam for Mueller Pro

Compression Mesh Fabric Wingtex 320gsm Powernet Fabric

Great Savings On Stretchy And Stylish Wholesale Compression

Neotech Care Calf Support Sleeve - Elastic & Breathable Knitted

- By Anthropologie Seamless Renna Second Skin Bralette

HÚNGARO DO FLAMENGO, MARKO FILIPOVITY DESTACA RÁPIDA ADAPTAÇÃO AO CLUBE E MOMENTO VIVIDO NO NBB

HÚNGARO DO FLAMENGO, MARKO FILIPOVITY DESTACA RÁPIDA ADAPTAÇÃO AO CLUBE E MOMENTO VIVIDO NO NBB Black Sexy Latex Catsuit Swimsuit With Penis Sheath Short Sleeves

Black Sexy Latex Catsuit Swimsuit With Penis Sheath Short Sleeves- The Bra Box - Smoothing Bali Bra Box Set 🖤Bali One Smooth U Balconette Shaping Bra X2 Size: 42DD Also available in sizes 44DD & 40D Price: $395.00 TTD and includes all

Leg Braces, Sleeves and Supports - 60-Day Moneyback Guarantee

Leg Braces, Sleeves and Supports - 60-Day Moneyback Guarantee- Antique Silver Egyptian Belly Dance Belt with Coins