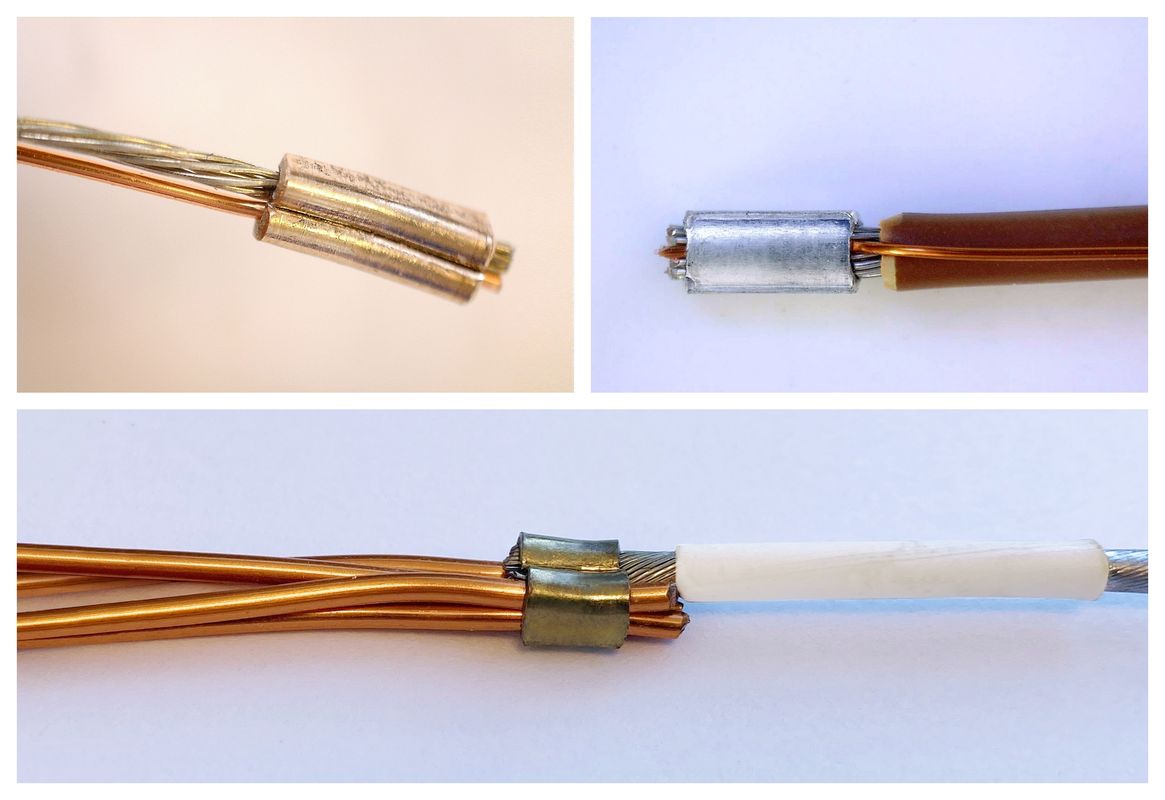

Hot Crimping for Joining Magnet Wires, 2012-04-02

5 (193) In stock

Using new and innovative technology can be risky, but it can often be rewarding. European electric-motor manufacturers Bosch, Siemens and Volkswagen realized this in 2011 after discovering hot crimping. For decades, these companies used machines or chemicals to strip the enamel coating off the ends of magnet wires before crimping them to copper ring terminals or sleeves. Hot crimping, in contrast, vaporizes the insulation during crimping of the wire and terminal or sleeve. By eliminating the stripping step, hot crimping enables manufacturers to increase productivity. . . .

Hot crimping technology features specially designed welding heads that quickly attach terminals to wire from 30 AWG to 350 MCM.

Pro'sKit 902-160 CrimPro Crimper for Wire Ferrules, AWG 2-4-6

EP3797709A1 - Ensemble de mise à feu comprenant un fusible

Duo-Crimp No. 300 Wire Stripper No. 7 Magic High-quality shaker with 400 wire end ferrules (0.5 - 2.5 mm²) according to DIN 46228

Crimp Set Pro

US20160024656A1 - Showerhead assembly and components thereof

Duo-Crimp No. 300 Wire Stripper No. 7 Magic High-quality shaker with 400 wire end ferrules (0.5 - 2.5 mm²) according to DIN 46228

Crimp Set Pro

US11171025B2 - Substrate processing device - Google Patents

55 Sets Servo Plug Male Female Connector Crimp Pin Cable Kit with

AUTO PIERCING technology for magnet wire: SM Contact starts

EP3797709A1 - Ensemble de mise à feu comprenant un fusible

CRIMPED TERMINATIONS GENERAL REQUIREMENTS

Cable Lug Crimping Tool-for Heavy Duty Wire Copper Lugs-Knoweasy - knoweasy

Tutorial: How to crimp connectors, strip wire and use heat shrink.

215343-1222 Molex Male Mini-Fit Jr. to Unterminated Crimped Wire

Soft Triangle Bra in Black with Leavers Lace

Soft Triangle Bra in Black with Leavers Lace Filha de Sheila Mello posa com gêmeos de Isa Scherer: titia fofa

Filha de Sheila Mello posa com gêmeos de Isa Scherer: titia fofa Sleeping While Pregnant: First Trimester

Sleeping While Pregnant: First Trimester Fit Seamless Cropped Leggings

Fit Seamless Cropped Leggings PetSafe 90-ft Static Wireless Pet Fence in the Wireless Pet Fences department at

PetSafe 90-ft Static Wireless Pet Fence in the Wireless Pet Fences department at American Airlines com 737 MAX para o Brasil - Flap International

American Airlines com 737 MAX para o Brasil - Flap International