Tailored laser beam shapes for welding of copper using green laser radiation

4.7 (280) In stock

Welding depth s for Cu-ETP as a function of laser power P and welding

Temperature curves when welding steel and copper based on [16]

Properties of the laser system Trumpf TruDisk 1020

High-speed images of fusing threshold (a), heat conduction welding (b)

Enhanced Scaling of Material Removal Rate with High Surface Quality Through Combined Laser Processes

Upper) X-ray video sequence of laser beam welding of copper using 1030

Selective laser melting (SLM) of pure copper using 515-nm green laser: from single track analysis to mechanical and electrical characterization

Beam Shaping for Laser Material Processing

Michael Schmidt - FAU Profilzentrum Solar

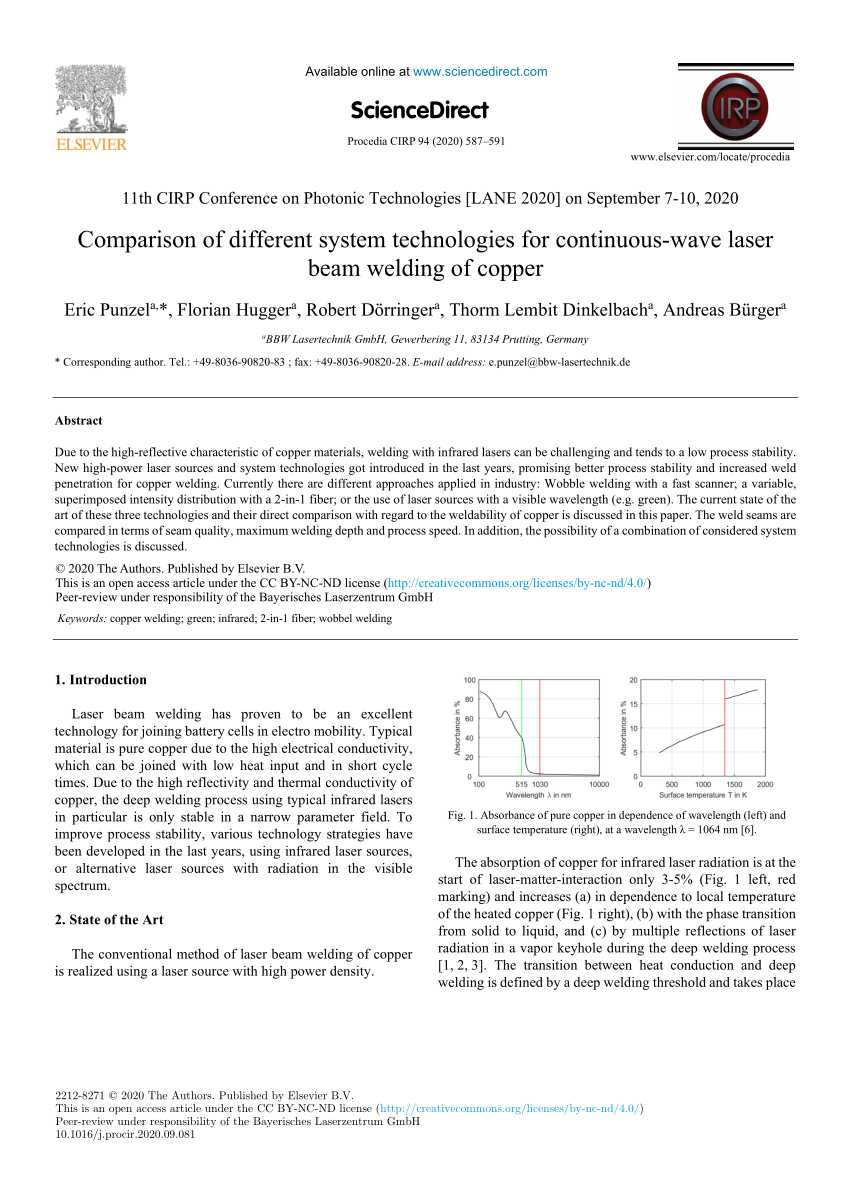

PDF) Comparison of different system technologies for continuous-wave laser beam welding of copper

Enhanced Scaling of Material Removal Rate with High Surface Quality Through Combined Laser Processes

Seam Formation in Laser Beam Micro-Welding with Spatial Power Modulation

TEM photo near joint interface of Type 304 steel and PET plastic, and

High-speed synchrotron X-ray image of laser beam welding of Cu-ETP with

PDF] Laserscribing of Thin Films Using Top-Hat Laser Beam Profiles

Fig. 7.5, Scheme of the laser processing with different spatially

Gauss- to-Top Hat beam shaper lenses

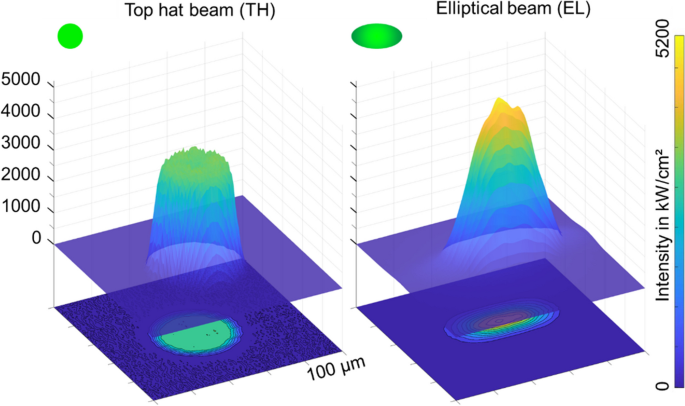

a) Typical top-hat profile of the excimer excitation beam at the

Black comfortlux bootcut total look with pockets

Black comfortlux bootcut total look with pockets D2C apparel brand unclip and specialty sock store Kutsushitaya by Tabio to begin sales of collaborated sock designs

D2C apparel brand unclip and specialty sock store Kutsushitaya by Tabio to begin sales of collaborated sock designs Best Yoga Headbands - Hot Yoga Headbands - Soul Flower Blog

Best Yoga Headbands - Hot Yoga Headbands - Soul Flower Blog creds @katebrockkkk on tiktok #black #flared #trousers #outfit #casual #blackflaredtrousersoutfitcasual

creds @katebrockkkk on tiktok #black #flared #trousers #outfit #casual #blackflaredtrousersoutfitcasual Women Sports Bra Zip Front Closure Strappy Crisscross Back Workout

Women Sports Bra Zip Front Closure Strappy Crisscross Back Workout Victoria's Secret Wicked by Victoria's Secret Eau De Parfum Spray

Victoria's Secret Wicked by Victoria's Secret Eau De Parfum Spray