Reducing black dots defects! Features of the purging pellet ecomaru - ecomaru, high cleaning purging pellet

4.5 (423) In stock

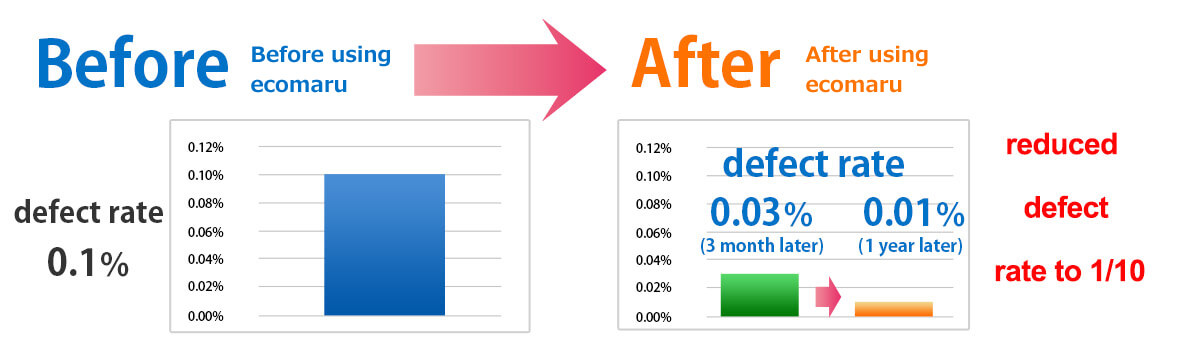

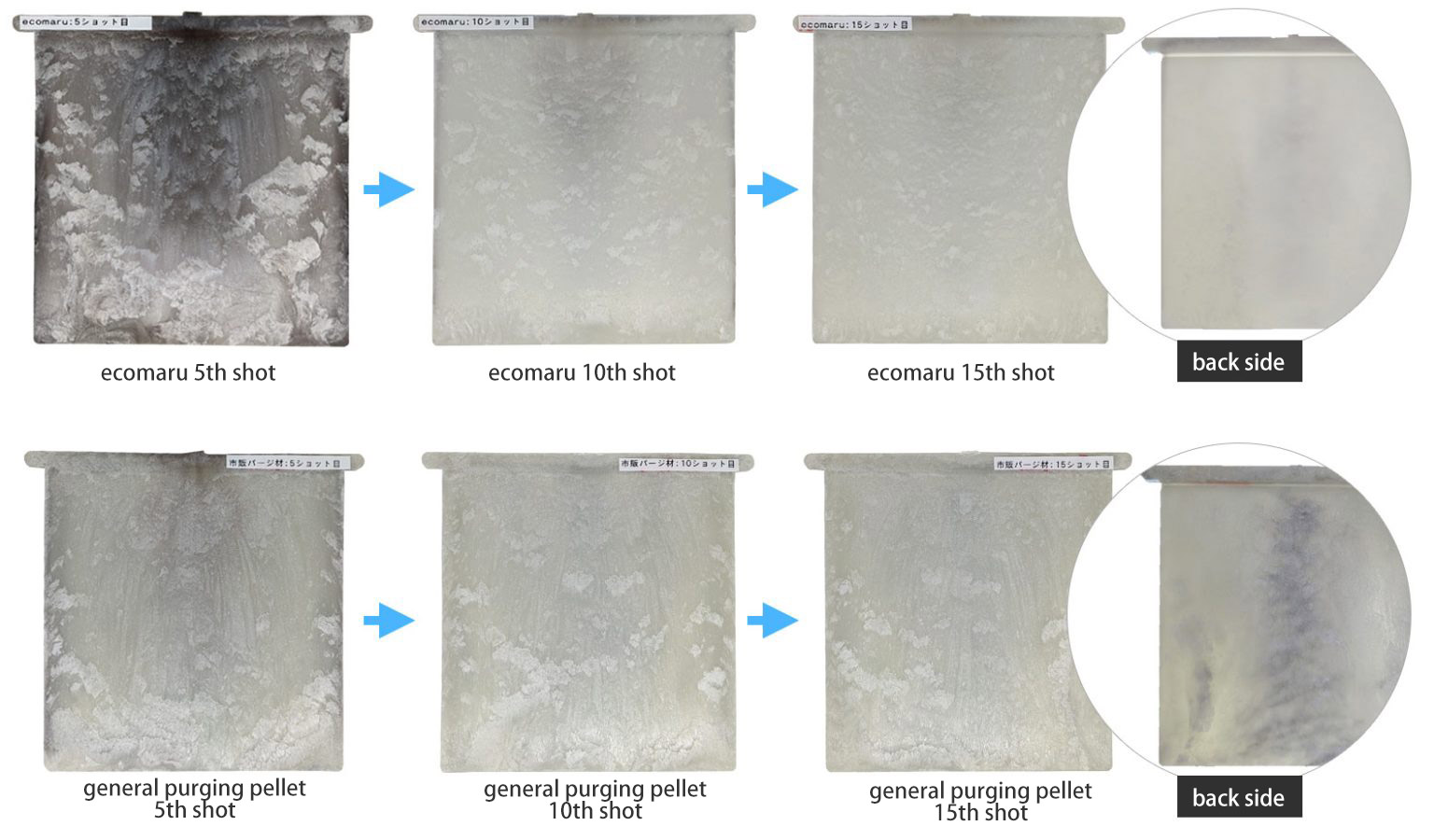

quot;ecomaru" is purging pellet specially developed and made for cleaning the inside of cylinders for injection molding machine. Highly mixing with GW (glass wool), the highest priority is on black dots removal performance. It makes great contributions to quality improvement by removing and preventing resin deterioration (burning and black dots) in cylinder that was not able to be completely removed by GF (glass fiber) and reducing the foreign material defect rate such as black dots defects.

Black Speck Removal

Plastic injection machine purging agent ecomaru cleaning video

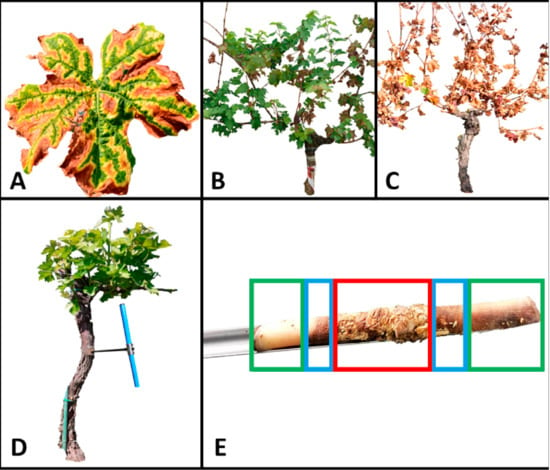

Trunk Surgery as a Tool to Reduce Foliar Symptoms in Diseases of

Reducing black dots defects! Features of the purging pellet

What are the Compost BMPs?, Region 5 Waste

Erosion Control Blankets

EroNet Photodegradable Erosion Control Blankets

Ecotex® All Purpose Screen Printing Hyper Haze (Quart

Black Speck Removal

Tokyo SME Support Center

Investigation of cigarette effect and elastic-plastic behavior of

Do It Yourself Pest Control Products & Supplies

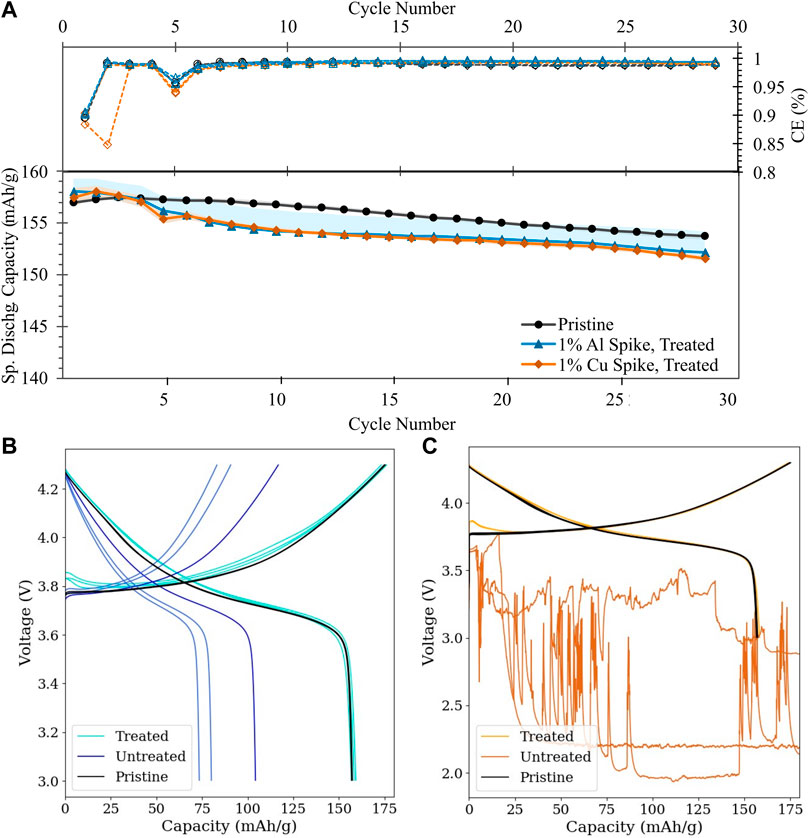

Frontiers Optimized purification methods for metallic

Tpu 95a Pellets Conductive Carbon Black Manufacturers and

Exhibitor List 2023

Defect Resolution Rate. The Defect Resolution Rate in UAT (User…, by Manpreet Buttar

Snowballs Cooling Underwear for Men (XX-Large) : : Health & Personal Care

Snowballs Cooling Underwear for Men (XX-Large) : : Health & Personal Care NEW! Baggu SET OF 3 STANDARD BAGS in HAPPY MIX — Washable Recycled Nylon Unisex

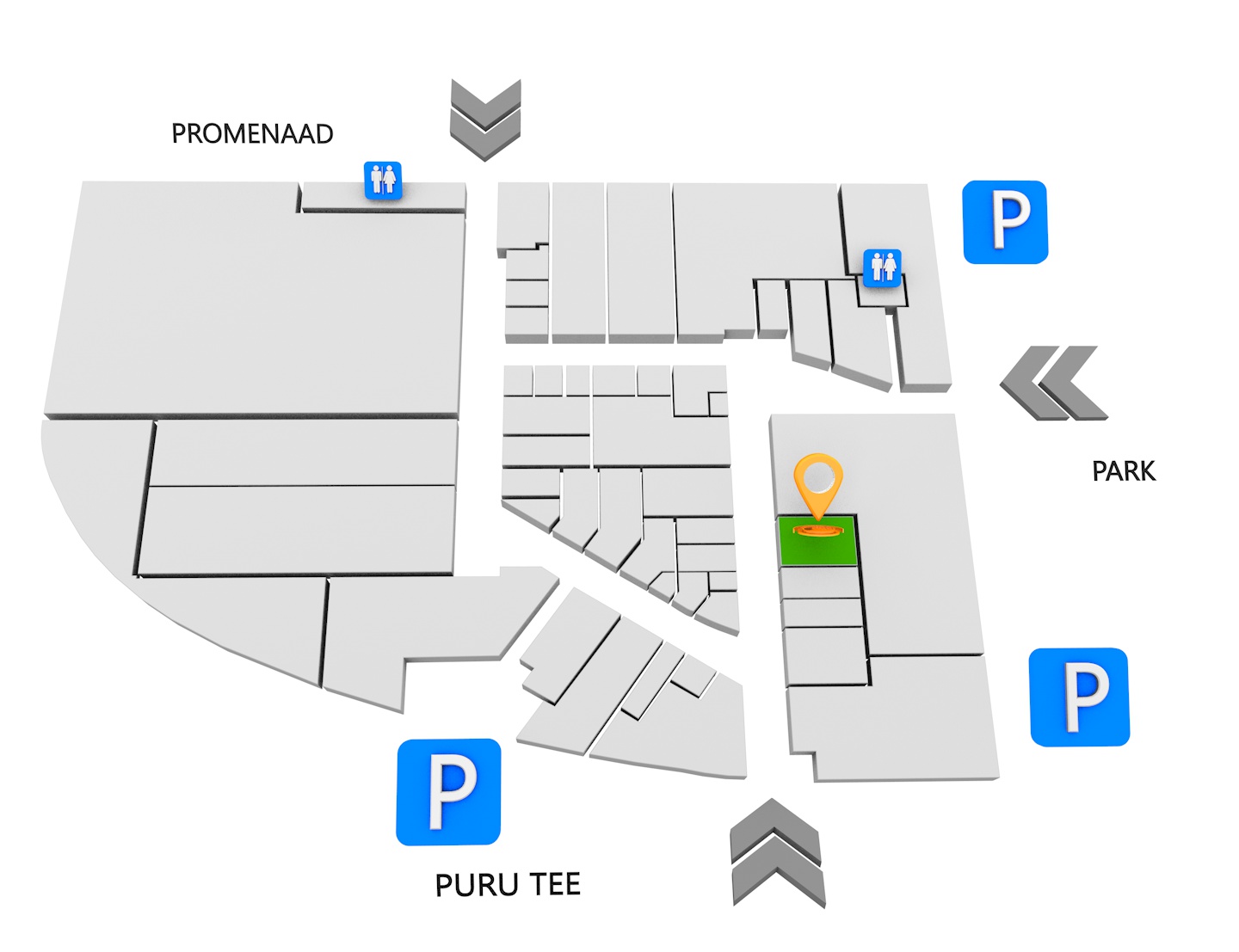

NEW! Baggu SET OF 3 STANDARD BAGS in HAPPY MIX — Washable Recycled Nylon Unisex Denim Dream - Pargi Keskus

Denim Dream - Pargi Keskus Wireless Womens Lace Bras Plus Size No Underwire Everyday Bra Full

Wireless Womens Lace Bras Plus Size No Underwire Everyday Bra Full Pantone and Highland Spring Release a Helpful Pee Chart Because Y'all Need to Hydrate – PRINT Magazine

Pantone and Highland Spring Release a Helpful Pee Chart Because Y'all Need to Hydrate – PRINT Magazine 2023 Ethical Underwear & Sustainable Bras & Lingerie (Fully Organic)

2023 Ethical Underwear & Sustainable Bras & Lingerie (Fully Organic)